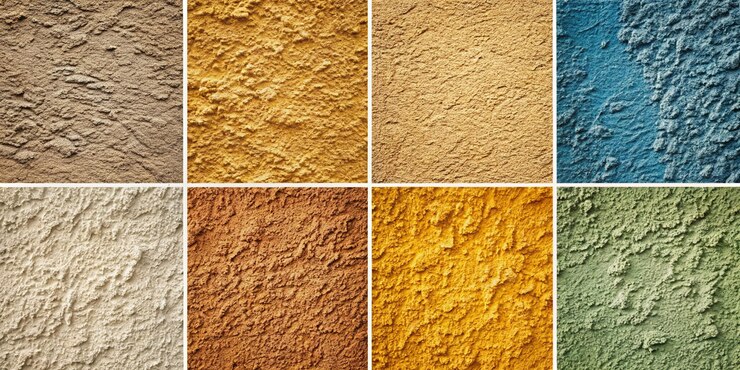

Concrete has evolved far beyond its traditional role as a plain, grey building material. Today, coloured concrete has become a popular choice for architects, designers, builders, and homeowners who want to combine durability with vibrant, aesthetic appeal.

By adding pigments, stains, or integral colorants to the concrete mix or surface, coloured concrete opens up endless possibilities for both interior and exterior applications.

In this comprehensive guide, we’ll explore what coloured concrete is, how it’s created, its advantages, design options, typical uses, maintenance requirements, and cost considerations.

Coloured concrete refers to concrete that has been tinted or pigmented to achieve a specific shade or tone. This can be done by adding color directly to the concrete mix, applying stains to the surface, or using decorative overlays. Unlike painted or coated surfaces, the color in coloured concrete is typically integrated into the material itself, ensuring long-lasting vibrancy that won’t chip or peel over time.

Whether you want earthy tones that blend with the natural environment or bold hues that make a statement, coloured concrete provides a durable, versatile, and attractive solution.

How is Coloured Concrete Made?

There are several methods for producing coloured concrete, each offering unique effects and levels of permanence:

1. Integral Colour

Integral colour is added directly to the concrete mix before pouring. This ensures that the colour is consistent throughout the slab, not just on the surface. Because the pigment permeates the entire thickness of the concrete, chips and wear won’t expose plain grey concrete beneath.

Integral colour is available in a wide range of shades, from subtle earth tones to vibrant contemporary hues.

2. Surface Colour Hardener

A colour hardener is broadcast onto the wet concrete surface after placement and then troweled in. This method not only imparts colour but also increases the surface’s hardness and abrasion resistance. It’s commonly used in decorative finishes like stamped concrete.

3. Acid Stains and Water-Based Stains

Acid stains chemically react with the concrete’s minerals to create variegated, translucent tones, often resembling natural stone or aged leather. Water-based stains, on the other hand, provide more uniform coverage and a broader palette of colors.

These stains are applied after the concrete has cured and are sealed for protection.

4. Concrete Dyes

Concrete dyes offer vibrant, intense colours and are often used for interior floors or polished concrete. They penetrate deeply and are typically applied to cured concrete.

5. Toppings and Overlays

When resurfacing old concrete, coloured overlays or micro-toppings can be applied. These thin layers can be stained, dyed, or integrally coloured to achieve the desired look.

Benefits of Coloured Concrete

Coloured concrete offers numerous advantages beyond its aesthetic appeal:

1. Design Versatility

With an extensive range of colours and application techniques, coloured concrete allows for unique, custom designs. It can replicate the look of natural stone, brick, tile, or even wood.

2. Durability

Because the colour is integral or bonded to the surface, it is long-lasting and resistant to chipping, fading, and peeling, especially when properly sealed.

3. Low Maintenance

Coloured concrete requires minimal upkeep. Simple cleaning and periodic resealing will keep it looking fresh for many years.

4. Cost-Effective

Compared to premium paving or flooring materials like natural stone or tiles, coloured concrete provides a similar aesthetic at a fraction of the cost, with lower long-term maintenance expenses.

5. Weather and UV Resistance

High-quality pigments and stains are designed to resist fading from sunlight and harsh weather conditions, making coloured concrete suitable for outdoor use.

6. Eco-Friendly Options

Many coloured concrete products use natural or recycled materials. Additionally, the long life span of concrete surfaces means less waste over time.

Common Applications of Coloured Concrete

Coloured concrete is suitable for a wide range of residential, commercial, and public projects.

Residential Uses

- Driveways: Enhance curb appeal with a coloured concrete driveway that complements your home’s exterior.

- Patios: Create inviting outdoor living areas with warm, natural tones or vibrant modern colours.

- Paths and Walkways: Add interest and continuity to your landscaping.

- Pool Surrounds: Combine slip resistance with style for safe, beautiful pool areas.

- Interior Floors: Coloured concrete floors provide a sleek, modern look for kitchens, living areas, and basements.

Commercial and Public Uses

- Shopping centres: Durable and attractive flooring that stands up to high foot traffic.

- Office buildings: Stylish, low-maintenance floors and outdoor areas.

- Public plazas and walkways: Aesthetic and functional surfaces that resist wear and weather.

- Educational and healthcare facilities: Hygienic, easy-to-clean flooring solutions.

Design Options for Coloured Concrete

The design possibilities with coloured concrete are virtually limitless:

- Monochrome or multi-tone finishes: Use a single colour for a clean, minimalist look or combine multiple shades for contrast and depth.

- Stamped patterns: Combine coloured concrete with stamping to mimic natural stone, brick, or wood textures.

- Exposed aggregate: Integrate coloured aggregates for added texture and visual interest.

- Saw cuts and scoring: Create geometric patterns or borders that enhance the design.

- Custom logos or graphics: Perfect for commercial spaces looking to reinforce branding.

Installation Considerations

Achieving the best results with coloured concrete requires proper planning and skilled execution.

Professional Expertise

While coloured concrete can look stunning, poor application can lead to blotchy colour, uneven finishes, or premature fading. It’s important to work with experienced contractors who understand how to mix, place, finish, and cure coloured concrete correctly.

Environmental Conditions

Weather can impact colour uniformity, especially for surface-applied colour methods. Factors like temperature, wind, and humidity must be managed during placement and curing.

Sample Panels

Creating a sample panel before starting a large project is a smart way to ensure the final colour and finish meet your expectations. Colours can vary depending on materials and conditions, so a mock-up helps align vision with reality.

Maintenance of Coloured Concrete

Keeping coloured concrete looking its best involves basic care:

- Regular cleaning: Sweep and wash surfaces periodically to prevent dirt build-up.

- Resealing: Sealing the concrete every few years helps preserve colour vibrancy, protect against stains, and reduce wear.

- Prompt stain removal: Clean up oil, grease, or chemical spills quickly to prevent staining.

- Avoid harsh chemicals: Use pH-neutral or manufacturer-recommended cleaners to avoid damaging the surface or sealer.

Cost of Coloured Concrete

The price of coloured concrete depends on several factors:

- The colouring method (integral colour tends to be more expensive than surface-applied stains or dyes).

- The complexity of the design (e.g., multi-colour patterns or stamped textures).

- The size of the area.

- The condition of the substrate (if resurfacing existing concrete).

As a general guide, coloured concrete may cost between 20% to 50% more than plain grey concrete, but the long-term aesthetic and functional value often outweighs the initial investment.

Coloured Concrete vs. Other Decorative Options

Coloured concrete offers an excellent balance of beauty, durability, and affordability. Unlike painted surfaces that can peel or chip, coloured concrete integrates the pigment into the material, ensuring long-lasting colour. Compared to pavers or natural stone, coloured concrete offers easier maintenance and fewer joint lines where weeds or moss might grow. Its versatility and design flexibility make it suitable for projects large and small, modern or traditional.

Common Myths About Coloured Concrete

“Coloured concrete fades quickly.”

When high-quality pigments and sealers are used, and proper maintenance is performed, coloured concrete can retain its vibrancy for decades.

“It’s only for outdoor use.”

Coloured concrete is just as effective indoors. It provides a durable, low-maintenance, and stylish alternative to tiles, timber, or carpet.

“It’s hard to match colours on repairs.”

While matching existing coloured concrete can be challenging, skilled contractors can blend colours effectively or use design features like borders to mask transitions.

Conclusion: Is Coloured Concrete Right for Your Project?

Coloured concrete is a smart choice for anyone looking to elevate the look of their indoor or outdoor spaces without sacrificing durability or functionality. From modern residential designs to large-scale commercial projects, it offers unmatched flexibility, longevity, and value.

Whether you prefer subtle earth tones that harmonize with nature or bold colours that make a statement, coloured concrete provides a canvas limited only by your imagination. With proper installation and care, it will serve as a beautiful, hard-wearing surface for years to come.